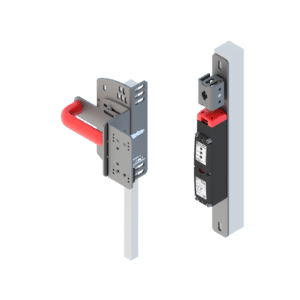

FEP Electromagnetic safety device with separated actuator-Plastic casing

Price 12000 INR/ Piece

FEP Electromagnetic safety device with separated actuator-Plastic casing Specification

- Finish Type

- Matte

- Number of Module

- Single

- Rated Voltage

- 24V DC

- Temperature Range

- -25C to +70C

- Mechanical Life

- 1,000,000 operations

- Response Time

- <20 ms

- Max. Current

- 2A

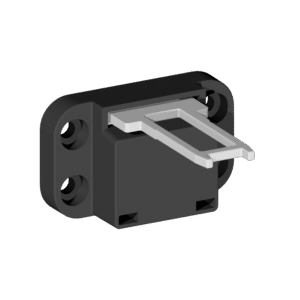

- Circuit Type

- NO/NC Double Break Contacts

- Automation Grade

- Industrial Automatic

- Protection Level

- IP67

- Product Type

- Electromagnetic Safety Device with Separated Actuator

- Material

- Plastic Casing (High-strength thermoplastic)

- Insulation Resistance

- >100 M (at 500 VDC)

- Contact Resistance

- <100 m

- Max. Voltage

- 250V AC/DC

- Operating Temperature

- -25C to +70C

- Stoke

- 7 mm

- Size

- 90 x 30 x 25 mm

- Color

- Red/Yellow body with black actuator

- Weight

- Approx. 90g

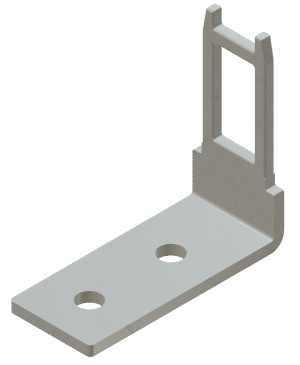

- Mounting Type

- DIN rail or surface mount

- Current Rating

- 2A

- No Of Poles

- 2

FEP Electromagnetic safety device with separated actuator-Plastic casing Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- All India

- Certifications

- CE Certified

About FEP Electromagnetic safety device with separated actuator-Plastic casing

Electromagnetic safety device with separated actuator

Electromagnetic device with separated actuator, FEP series, represents a reliable and actual solution as interlocking device with guard. This electromagnetic safety switch is controlled by a solenoid, which is able to block the actuator and act as safety interlock, in order to prevent the access to the protected area up to the persistence of the dangerous situation. The RFID coded version guarantees protection against easy bypass of the device, maintaining the features of reliability and solidity of Comepi products.

Advanced Industrial Safety Solution

The FEP Electromagnetic safety device is purpose-built to enhance machine guard and safety door monitoring. Its electromagnetic technology and coded magnet actuator offer high security, preventing unauthorized or unsafe access. Compliance with international safety standards ensures its suitability for a wide range of industrial automation environments.

Durable and Versatile Construction

Encased in high-strength, glass-filled thermoplastic, this device offers superior resistance to industrial wear, vibration, and harsh conditions. Rated IP67, it is well-protected against dust and moisture, with an operating temperature range from -25C to +70C. Easy mounting options make it adaptable to diverse installation scenarios.

Reliable Performance and Efficiency

With a rapid response time of less than 20ms and mechanical durability for over a million operations, the FEP safety device supports critical safety functions without interruption. The NO/NC double break contacts enable efficient status detection, while low contact resistance and high insulation secure reliable operation in automated systems.

FAQs of FEP Electromagnetic safety device with separated actuator-Plastic casing:

Q: How does the FEP Electromagnetic safety device enhance machine safety?

A: The device enhances safety by using a separate coded magnet actuator and electromagnetic switching to securely interlock safety doors or guards, preventing accidental or unauthorized machine access when in operation.Q: What installation options are available for this safety device?

A: This safety device can be mounted via DIN rail or directly onto surfaces. It supports cable entry sizes of M16 or M20 and can be installed in any orientation, offering flexibility for various industrial setups.Q: When should I consider using this safety interlock device in my facility?

A: The FEP safety device should be used whenever machine safety, guard interlocking, or door monitoring is critical, especially in environments requiring compliance with CE, EN ISO 14119, and EN60947-5-1 safety standards.Q: Where can the device be installed to ensure maximum effectiveness?

A: It is best installed on access points such as safety doors, guards, and protective covers of machinery, ensuring the interlock is engaged whenever unauthorized access could pose a risk to operators.Q: What is the process for connecting and operating the device?

A: Connect the device to your control circuit using the M16/M20 cable entry and ensure proper wiring of the 1NO+1NC contacts. Once installed, the actuator engages with the main body to activate the electromagnetic safety interlock, signaling the machines control system accordingly.Q: How does the FEP safety device perform in harsh industrial environments?

A: With its glass-filled thermoplastic housing, IP67 protection, and resistance to vibrations (10-55Hz), shocks (30g), and extreme temperatures, the device is built for durability and reliable operation in tough industrial conditions.Q: What are the key benefits of using this safety device in industrial automation?

A: Key benefits include enhanced workplace safety, compliance with international standards, high durability, rapid response, and minimal maintenance due to its robust construction and long mechanical life (1,000,000 operations).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electromechanical safety switches with solenoid locking Category

Guard Locking safety switches

Price 14000-30000 INR / Piece

Minimum Order Quantity : 10 Pieces

Contact Resistance : 25 m (initial value)

Product Type : Guard Locking Safety Switch

Rated Voltage : 240V AC

Material : Engineering Plastic and Metal

FEP-LED Electromagnetic safety device with separated actuator-Plastic casing With LED signalling for easy identification of the lock status

Price 15000 INR / Piece

Minimum Order Quantity : 10 Pieces

Contact Resistance : 50 m

Product Type : Electromagnetic safety device with separated actuator

Rated Voltage : 24V DC (LED indicator)

Material : Highstrength industrial plastic

Safety Handles for safety switches

Price 20000-26000 INR / Piece

Minimum Order Quantity : 5 Pieces

Contact Resistance : 50 m

Product Type : Safety Handle for Safety Switch

Rated Voltage : 400V

Material : High Impact Thermoplastic (PA66) / Polycarbonate

Key Release Electromagnetic Safety Device

Price 15000 INR / Piece

Minimum Order Quantity : 10 Pieces

Contact Resistance : 50 m

Product Type : Key Release Electromagnetic Safety Device

Rated Voltage : 24V DC (Coil)

Material : Highimpact ABS & Metal

|

ISAC ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry