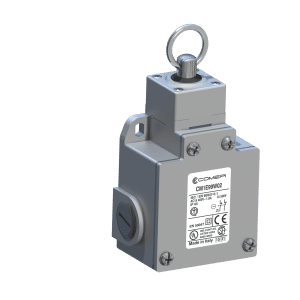

Pull wire limit switches (Traction operation)

Price 3000-4500 INR/ Piece

Pull wire limit switches (Traction operation) Specification

- Temperature Range

- -25°C to +70°C

- Number of Module

- Single module

- Mechanical Life

- >1 million operations

- Rated Voltage

- 250V AC

- Automation Grade

- Manual

- Max. Current

- 10A

- Protection Level

- IP65

- Response Time

- Instantaneous mechanical action

- Circuit Type

- 1NO+1NC

- Finish Type

- Textured coating

- Product Type

- Pull wire limit switch (Traction operation)

- Material

- Reinforced Glass Fiber Polyamide Body, Zinc-plated Metal Parts

- Insulation Resistance

- 100MΩ (at 500V DC)

- Contact Resistance

- ≤25mΩ

- Max. Voltage

- 500V AC/DC

- Operating Temperature

- -25°C to +70°C

- Stoke

- Manual wire pull (traction)

- Size

- 145mm x 80mm x 56mm

- Color

- Grey / Yellow actuator

- Weight

- Approx. 570g

- Mounting Type

- Surface mounting (4-point) with cable entry

- Current Rating

- 10A

- No Of Poles

- 2

- Switch Type

- Snap action

- Vibration Resistance

- 10~55Hz, 1.5mm double amplitude

- Ambient Humidity

- Max. 95% RH (non-condensing)

- Contact Material

- Silver alloy

- Actuator Type

- Steel wire (pull cord)

- Reset Operation

- Manual reset required after actuation

- Cable Entry Size

- M20 x 1.5

- Shock Resistance

- 30G (approx.)

- Conductor Connection

- Screw type terminal, max 2.5mm²

Pull wire limit switches (Traction operation) Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 6 Week

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- CE

About Pull wire limit switches (Traction operation)

Pull wire limit switches

Limit switches with rope for simple stop, without manual reset. These limit switches are useful for signalling and for commanding doors or similars. Available also in special version with double signal in traction or release, helpful to signal an eventual loss of tension due to the breaking of the rope.

Superior Safety and Reliability

Engineered with a 1NO+1NC snap action contact arrangement and silver alloy contacts, the Pull Wire Limit Switch guarantees rapid response and dependable performance during emergency stops. Its manual reset function ensures deliberate startup procedures, minimizing accidental restarts and increasing workplace safety.

Built for Industrial Environments

Housed in a reinforced glass fiber polyamide body with zinc-plated components, this switch withstands challenging industrial settings. Boasting an IP65 ingress rating, high shock (30G) and vibration resistance (10-55Hz, 1.5mm), it is ideal for harsh environments without sacrificing operational integrity.

Flexible Mounting and Easy Maintenance

Designed for surface mounting with a convenient four-point system, the switch accommodates a wide range of installation setups. Screw-type terminals for up to 2.5mm2 conductors simplify wiring, while straightforward manual reset makes maintenance both easy and secure.

FAQ's of Pull wire limit switches (Traction operation):

Q: How does the pull wire limit switch operate during an emergency?

A: During an emergency, pulling the attached steel wire (pull cord) actuates the switch. The internal snap action mechanism instantly changes the status of the contacts (1NO+1NC), triggering an immediate response to shut down, stop, or control connected systems for enhanced safety.Q: What environments are suitable for installing this pull wire limit switch?

A: The switch is suitable for industrial settings requiring robust safety controls. Its IP65 rating, reinforced polyamide body, and resistance to shock and vibration make it ideal for harsh or dusty areas, including manufacturing lines and automated machinery environments.Q: When is it necessary to manually reset the switch?

A: A manual reset is required after every actuation. This ensures intentional reactivation, preventing accidental restarts and improving operational safety by allowing personnel to assess the situation before system restart.Q: Where should the device be mounted for optimal performance?

A: For best results, the switch should be surface-mounted using the designated four-point system at accessible locations along conveyor lines, processing machinery, or other equipment requiring emergency shutoff. Proper placement allows quick access in critical situations.Q: What is the process for connecting wires to the switch?

A: Wires are connected via the screw-type terminals provided, accommodating conductors up to 2.5mm2 in size. Ensure the cable enters through the M20 x 1.5 entry and tighten the terminals securely for reliable operation and safety compliance.Q: What are the benefits of using a snap action, manual reset limit switch in industrial automation?

A: The snap action mechanism ensures instantaneous and reliable signal transmission for safety-interlock applications. With manual reset, it prevents accidental system restarts, promoting deliberate and secure corrective actions, reducing downtime and enhancing productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pull wire Limit switches Category

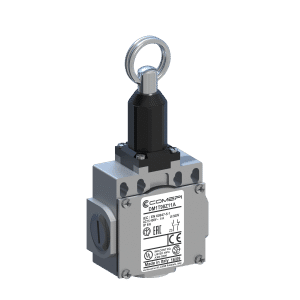

Pull wire limit switches – Operation only in traction

Price 4500 INR / Piece

Minimum Order Quantity : 10 Pieces

Temperature Range : 25°C to +70°C

Color : Grey/Red

Mounting Type : Surface Mount

Number of Module : Single

AM-Metal body 30mm

Price 3500 INR / Piece

Minimum Order Quantity : 10 Pieces

Temperature Range : 25°C to +55°C

Color : Metallic (Silver Grey)

Mounting Type : Panel Mount

Number of Module : Single

AP-Plastic 30 mm

Price 3500 INR / Piece

Minimum Order Quantity : 10 Pieces

Temperature Range : 25°C to +55°C

Color : Black

Mounting Type : Panel Mounting

Number of Module : Single

DP-Plastic Body 50 mm

Price 4500 INR / Piece

Minimum Order Quantity : 10 Pieces

Temperature Range : 20°C to 60°C

Color : Grey

Mounting Type : Panel Mount

Number of Module : Single Module

|

ISAC ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry