Safety switch Hygtech

Price 18000 INR/ Piece

Safety switch Hygtech Specification

- Features

- Tamper Resistant, Corrosion Proof, Easy Installation, High Reliability

- Response Time

- <10 ms

- Cable Length

- 2 meters

- Operating Temperature

- -25C to +70C

- Application

- Machine Safety, Access Control

- Sensitivity

- Standard

- Signal Type

- Digital

- Mounting Type

- Panel/Surface Mount

- Power Consumption

- Low Power (~2W)

- IP Rating

- IP67

- Interface

- Cable/Terminal Block

- Wireless

- No

- Sensor Type

- Electromechanical

- Product Type

- Safety Switch

- Material

- Stainless Steel, High Grade Engineering Plastic

- Input

- 24V DC

- Output

- NO+NC Contacts

- Function

- Machine Guarding, Safety Interlock

- Usage

- Industrial Automation, Safety Circuits

- Accuracy

- High Precision

- Voltage

- 24V DC

- Weight

- Approx. 250 grams

Safety switch Hygtech Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, Middle East

- Main Domestic Market

- All India

- Certifications

- CE certified

About Safety switch Hygtech

SAFETY SWITCH HYGTECH

New range of Hygtech safety sensors designed for hazardous machine guards, manufactured in 316L stainless steel housings, they represent the solution in the food industry.

This innovation meets the requirements of safety and hygiene standards (according to EN 12268, EN 16722, NSF/ANSI/3-A)

Temperature: -25AAAAC to + 80AAAAC

Protection class: IP69K

Supply voltage: 9 to 30 VDC

Two mounting versions:AA

AR: Rear mounting

AV: Front mounting

Superior Safety with Robust Materials

Hygtech's safety switch features an FDA grade polycarbonate enclosure combined with corrosion-proof stainless steel and high-grade engineering plastic, ensuring resilience against harsh industrial conditions. Its IP67 rating offers full protection against dust and water, making it suitable for challenging environments requiring strict hygiene and durability standards.

Advanced Performance for Industrial Automation

With a 2A contact rating and 24V DC input, the Hygtech safety switch delivers high precision, fast digital response under 10 milliseconds, and low power consumption. Its mechanical life exceeds one million operations, making it a dependable choice for continuous use in machine safety circuits and automated access control systems.

FAQ's of Safety switch Hygtech:

Q: How is the Hygtech safety switch installed in industrial environments?

A: The Hygtech safety switch supports panel or surface mounting. Its robust enclosure and 2-meter cable allow flexible installation on machinery or access control points. Installation is straightforward via cable/terminal block interface, and its tamper-resistant design ensures secure placement.Q: What benefits does the FDA grade polycarbonate enclosure provide?

A: The FDA grade polycarbonate enclosure offers high impact resistance and compliance with stringent hygiene standards. It ensures durability, corrosion resistance, and suitability for use in food processing and pharmaceutical industries where material safety is critical.Q: When should I use the Hygtech safety switch in automation systems?

A: Use the Hygtech safety switch whenever machine guarding, safety interlock, or access control is required to prevent unauthorized or unsafe machine operation. Its high reliability and quick response time make it ideal for protecting personnel and equipment during industrial processes.Q: Where is the Hygtech safety switch typically applied?

A: This safety switch is commonly deployed in machine safety circuits, industrial automation setups, and access control systems, especially in environments that demand high hygiene standards or corrosion resistance, such as manufacturing facilities in France.Q: What is the process for integrating the safety switch into safety circuits?

A: Integration involves connecting the switch output contacts (1NO+1NC) directly to the industrial safety circuit using the supplied cable or terminal block. The digital signal type and standard sensitivity ensure compatibility with most automation controllers and relay logic.Q: How does the key-operated actuator enhance security?

A: The key-operated actuator increases security by restricting machine activation only to authorized personnel, minimizing unwanted access, and reducing risks of tampering or accidental engagement during operation.Q: What advantages does the switch offer regarding operational reliability and precision?

A: The Hygtech safety switch boasts high accuracy and reliable digital signaling, withstanding over a million operations and resisting vibration. This minimizes maintenance needs while guaranteeing consistent performance and safety for long-term industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Contact Stainless Steel Housing Safety Switch Category

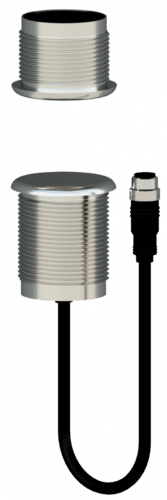

Stainless steel housing safety switches (Non-contact type)

Price 12000-18000 INR / Piece

Minimum Order Quantity : 5 Pieces

Weight : Approx. 250 g

Response Time : < 10 ms

Features : Tamperresistant, corrosionproof, hygienic design

Function : Noncontact interlocking safety switch

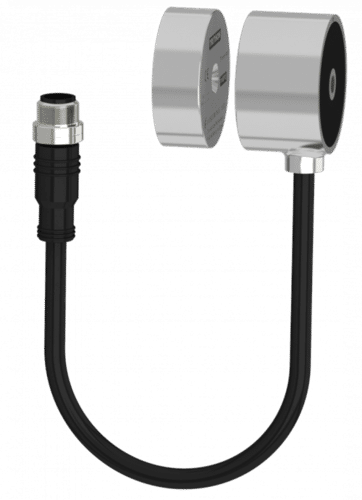

7SSR-HYG-MKT - SAFETY SENSOR

Price 15000 INR / Piece

Minimum Order Quantity : 5 Pieces

Weight : 125g

Response Time : 10 ms

Features : Dustproof, Vibration Resistant, Tamper Evidence LED

Function : Object & Human Sensing

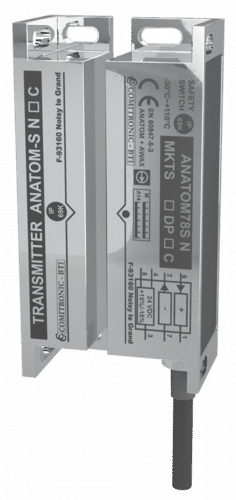

TRITHON N MKTS - TRITHON P MKTS - High temperature safety switch

Price 18000 INR / Piece

Minimum Order Quantity : 10 Pieces

Weight : Approx. 140g

Response Time : <10s

Features : Vibration resistant, resettable, compact design

Function : Temperature monitoring and safety cutoff

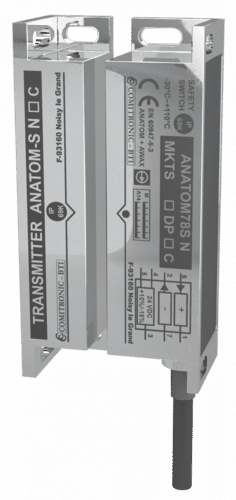

ANATOM78S-N-MKTS - Stainless steel non-contact safety Switch 316L

Price 18000 INR / Piece

Minimum Order Quantity : 5 Pieces

Weight : Approx. 300g

Response Time : <10 ms

Features : Tamper resistant, corrosionproof, highpressure washdown safe

Function : Machine safety interlocking

|

ISAC ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry