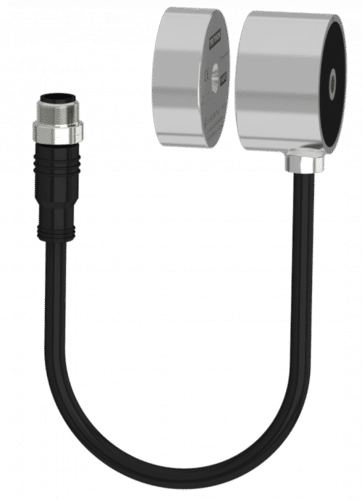

OPTO2S - Miniature safety Switch

Price 8000-10000 INR/ Piece

OPTO2S - Miniature safety Switch Specification

- Max. Current

- 5A

- Finish Type

- Smooth

- Protection Level

- IP67

- Temperature Range

- -25C to +70C

- Number of Module

- 1

- Mechanical Life

- >1,000,000 operations

- Circuit Type

- SPDT

- Response Time

- 20 ms

- Automation Grade

- Automatic

- Rated Voltage

- 250V AC

- Product Type

- Miniature Safety Switch

- Material

- Thermoplastic housing, Metal actuator

- Insulation Resistance

- 100 M (at 500V DC)

- Contact Resistance

- 25 m (initial)

- Max. Voltage

- 250V AC

- Operating Temperature

- -25C to +70C

- Stoke

- 13 mm

- Size

- 55 x 18 x 13 mm

- Color

- Black and Red

- Weight

- approx. 23g

- Mounting Type

- Panel Mount

- Current Rating

- 5A

- No Of Poles

- 1

- Electrical Life

- 100,000 cycles (at rated load)

- Ambient Humidity

- 45%85% RH

- Contact Type

- Snap Action

- Terminal Type

- Screw terminal

- Release Force

- approx. 0.2N 1N

- Actuator Type

- Rotary lever

- Vibration Resistance

- 10-55 Hz, amplitude 1.5 mm

OPTO2S - Miniature safety Switch Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- CE certified

About OPTO2S - Miniature safety Switch

OPTO2S - MINIATURE SAFETY SWITCH

Position control for doors / casings on hazardous machinery

Contactless encoded electronic sensor with relay

Category 3 total safety management without an external controller

12V version for embedded applications

Level of performance without an external controller: PL = c

Level of performance with AWAX controller: up to PL = e

Safety category without an external controller: 1

Cycle before dangerous failure: B10d = 2,000,000 at 50mA

Max. activation distance: 10 mm, 2 mm hysteresis

Safety contacts: 2 x NO 250 mA/48V redundant

Detection encoding: mono-code inviolable

Indicator: LED indicates code recognition

Reset: automatic

Attachment: 4 tamper-proof M3 screws (optional ref: BH3)

Mounting position: 2 (double wall brackets)

Material: PA6

Electrical Connection: 3, 6, 12m cable (UL2464 PVC)

Water resistance: IP 68

Temperature: -20AAC to +60AAC

Marking: pad printing + serial no. for traceability

Durability and Safety in Compact Design

The OPTO2S safety switch is engineered to balance compact form and robust function. Its sturdy thermoplastic housing and metal actuator withstand rigorous use, boasting more than one million mechanical operations. The IP67 protection rating shields the switch from dust and water, guaranteeing dependable performance even in industrial environments. Thanks to its snap action contacts and reliable electrical characteristics, this switch provides consistent operation essential for safety-critical applications.

Efficient Installation and Versatility

Measuring only 55 x 18 x 13 mm and weighing approximately 23 grams, the OPTO2S is ideal for space-saving panel mount installations. Its screw terminal design simplifies wiring, while the SPDT circuit supports flexible connectivity. The wide operating temperature and humidity tolerance, along with responsive performance, make it suitable for diverse automation setups whether in export, import, trade, or supplier distribution - particularly across France and international markets.

FAQ's of OPTO2S - Miniature safety Switch:

Q: How is the OPTO2S safety switch typically installed for industrial use?

A: The OPTO2S safety switch is designed for panel mount installation. Its compact size and screw terminal connections make it straightforward to integrate into control panels or machinery, providing secure and reliable attachment for safety circuit applications.Q: What operational environments is this miniature safety switch suited for?

A: Thanks to its IP67 protection, robust thermoplastic body, and a working temperature range from -25C to +70C, the OPTO2S functions reliably in harsh industrial environments with high humidity (45%-85% RH) and frequent vibration.Q: When should the OPTO2S be used in an automation system?

A: It should be used when compact, fast-acting safety is required-especially for machinery needing a rotary actuator and applications that demand up to 100,000 electrical and over 1,000,000 mechanical cycles. Its quick 20 ms response enhances safety in automated setups.Q: What are the benefits of the snap action contact mechanism in this switch?

A: Snap action contacts deliver precise, rapid switching, minimizing arching and wear. This feature extends the electrical life of the switch and ensures consistent, reliable actuation under rated loads, contributing to long-term durability.Q: How does the OPTO2S maintain safety in high-vibration environments?

A: With a vibration resistance of 10-55 Hz at 1.5 mm amplitude, the OPTO2S is specifically designed to maintain stable operation and accurate actuation even in areas exposed to constant mechanical vibrations, ensuring uninterrupted safety mechanisms.Q: Where does the OPTO2S source its robust insulation and contact resistance from?

A: The switch uses high-grade insulation materials to achieve 100 M insulation resistance (at 500V DC) and initial contact resistance 25 m, providing excellent electrical isolation and reliable current flow. Combined with its high-rated voltage and current parameters (250V AC, 5A), this ensures safe operation.Q: What is the process of maintaining the OPTO2S in the field?

A: Routine inspection typically involves checking the actuator movement, cleaning the external enclosure if necessary, and ensuring the screw terminals are tightened properly. The switch's robust design means it requires minimal maintenance for long service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non- contact Coded electronics Safety Switches Category

RFID Coded safety switches

Price 7000-12000 INR / Piece

Minimum Order Quantity : 10 Pieces

Number of Module : Single

Size : 73 x 25 x 13 mm

Temperature Range : 25C to +70C

Finish Type : Textured

Food & pharma graded stainless steel housing safety switches

Price 12000-18000 INR / Piece

Minimum Order Quantity : 10 Pieces

Number of Module : Single

Size : 110 x 40 x 40 mm

Temperature Range : 25C to +80C

Finish Type : Mirror/Matte Polished

7SSR24V - Cylindrical safety Switch

Price 14000 INR / Piece

Minimum Order Quantity : 5 Pieces

Number of Module : Single

Size : 22mm x 65mm Length

Temperature Range : 25C to +70C

Finish Type : Matte

Safety switches for high temperature applications

Price 20000 INR / Piece

Minimum Order Quantity : 5 Pieces

Number of Module : Single

Size : 60 x 30 x 95 mm

Temperature Range : 40C to 250C

Finish Type : CorrosionResistant

|

ISAC ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry