RFID Coded safety switches

Price 7000-12000 INR/ Piece

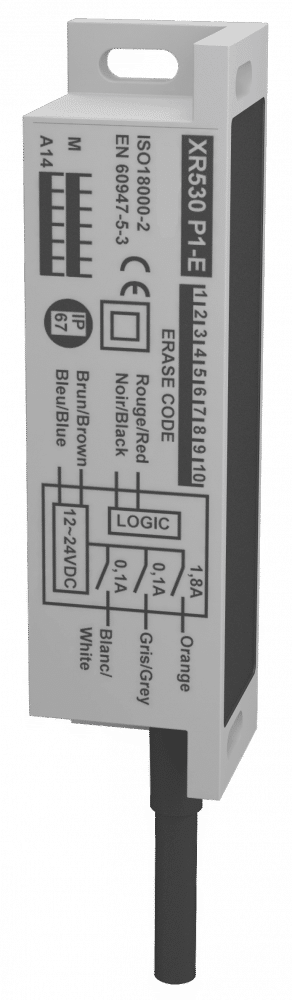

RFID Coded safety switches Specification

- Circuit Type

- Break Before Make

- Temperature Range

- -25C to +70C

- Rated Voltage

- 24V DC

- Response Time

- <10 ms

- Max. Current

- 2A

- Mechanical Life

- >10 million operations

- Number of Module

- Single

- Automation Grade

- Automatic

- Finish Type

- Textured

- Protection Level

- IP67

- Product Type

- RFID Coded Safety Switch

- Material

- High Grade Thermoplastic

- Insulation Resistance

- >100 M

- Contact Resistance

- <100 m

- Max. Voltage

- 250V AC/DC

- Operating Temperature

- -25C to +70C

- Stoke

- 10 mm

- Size

- 73 x 25 x 13 mm

- Color

- Red/Yellow/Black

- Weight

- Approx. 40g

- Mounting Type

- Surface/Panel Mount

- Current Rating

- 2A

- No Of Poles

- 1NO+1NC

RFID Coded safety switches Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- CE certified

About RFID Coded safety switches

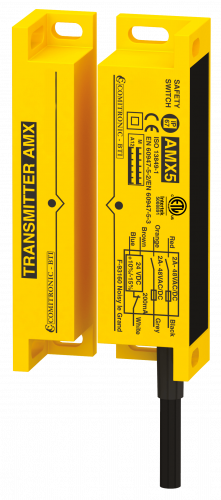

XORF-SA - Non-autonomous safety switch with RFID coding

Controls the position of security doors with RFID encoding for wheeled vehicles

RFID sensor with 16 million codes

Suitable for metallic environments

Programmable code through auto-learning (no software or PC)

Level of performance with AWAX controller: up to PL = e

Safety category: up to 4 (EN 954-1) with AWAX controller

Time to dangerous failure: MTTFd = 40 years

Reliable Safety for Machine Guarding

Designed for industrial environments, these RFID coded safety switches guarantee dependable non-contact machine guard door monitoring. With IP67 protection, dual signal outputs, and superior shock and vibration resistance, equipment safety is maximized, even in harsh, wet, or dusty surroundings. The high-grade thermoplastic housing and intelligent RFID technology ensure robust protection for both operators and machinery.

Advanced Security through High-Level Coding

Each switch pair is uniquely RFID coded for maximum tamper resistance, fully compliant with EN ISO 14119 standards. This unique pairing enhances safeguarding by preventing unauthorised replacement or manipulation. Instant LED status indication (red/green) enables quick diagnostics, while break-before-make circuit design provides additional user safety.

Flexible, User-Friendly Integration

Installation is straightforward, with a standard M12 4-pin connector and surface or panel mounting options. The compact size, low power consumption, and customizable cable lengths facilitate effortless adaptation to diverse machine guarding setups. Fast response time and dual output options support seamless integration with existing automation controls.

FAQ's of RFID Coded safety switches:

Q: How does the RFID coded actuation work for safety switches?

A: The safety switch uses a coded RFID transponder to uniquely identify its paired actuator, operating without physical contact for up to 12 mm distance. This enhances security against tampering and ensures only the matched actuator can trigger the safety function.Q: What are the benefits of dual color LED indication on this safety switch?

A: The dual color LED (red/green) provides immediate visual feedback on the switch state, simplifying status checks and helping technicians quickly identify system conditions or faults for efficient maintenance.Q: When should I use an RFID coded safety switch for my machine guard door?

A: RFID coded safety switches are ideal for applications that demand high tamper resistance and compliance with strict safety standards (EN ISO 14119). They are especially beneficial when unique identification, non-contact operation, and robust environmental protection are needed for machine guard monitoring.Q: Where can this safety switch be installed in an industrial setup?

A: The switch is designed for surface or panel mounting on machine guard doors, and its rugged IP67 housing makes it suitable for wet or dusty industrial environments, including food processing, packaging, and manufacturing lines.Q: What is the process for integrating the safety switch into existing control circuits?

A: Integration is made simple via the M12 4-pin connector. The switch outputs PNP/NPN signals, compatible with a wide range of automation systems. Its break-before-make contact arrangement ensures reliable safety circuit disconnection and reconnection.Q: How does the unique RFID code enhance operational safety?

A: Each switch/actuator pair uses a unique code, preventing unauthorized substitution or bypassing the safety mechanism. This ensures only the correct actuator can activate the switch, aligning with the high-level coding requirements of EN ISO 14119.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non- contact Coded electronics Safety Switches Category

Food & pharma graded stainless steel housing safety switches

Price 12000-18000 INR / Piece

Minimum Order Quantity : 10 Pieces

Response Time : 20ms

Max. Current : 10A

Mechanical Life : >1,000,000 operations

Number of Module : Single

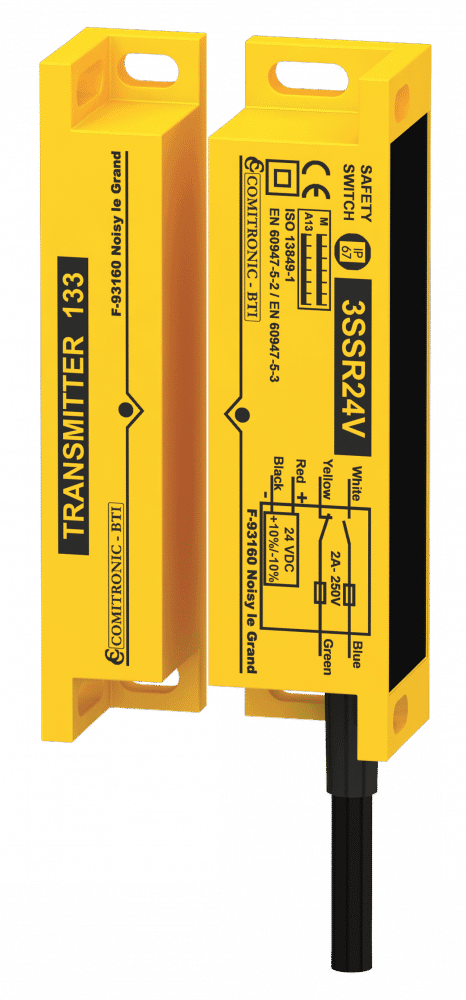

SSR - Safety Switch stand alone - Cat.1

Price 12000-15000 INR / Piece

Minimum Order Quantity : 5 Pieces

Response Time : 15 ms

Max. Current : 6A

Mechanical Life : 1,000,000 operations

Number of Module : Single

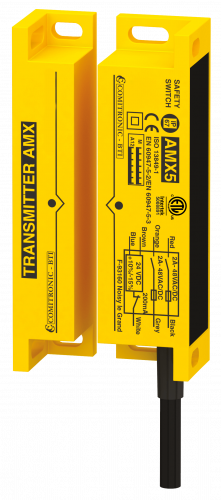

ANATOM - Non-autonomous contactless safety switch

Price 7000-12000 INR / Piece

Minimum Order Quantity : 5 Pieces

Response Time : 10 ms

Max. Current : 0.5A

Mechanical Life : >1,000,000 operations

Number of Module : Single Body

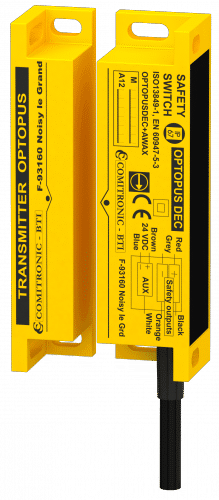

OPTOPUS DEC - MINIATURE NON-AUTONOMOUS SAFETY SWITCH

Price 5500-7500 INR / Piece

Minimum Order Quantity : 10 Pieces

Response Time : <20 ms

Max. Current : 2A

Mechanical Life : Over 1,000,000 cycles

Number of Module : Single

|

ISAC ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry